Projects

Product Groups

1000+ Projects

Completed

Our News

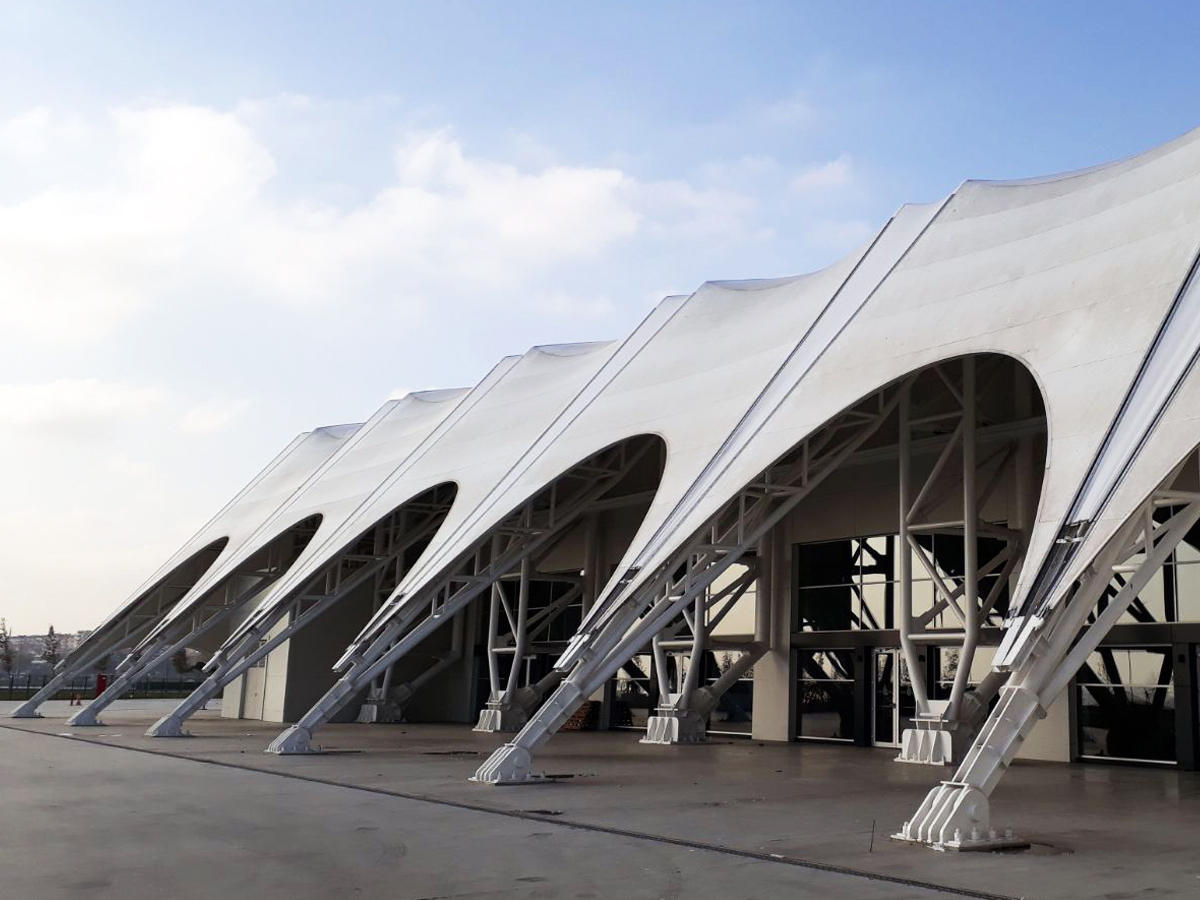

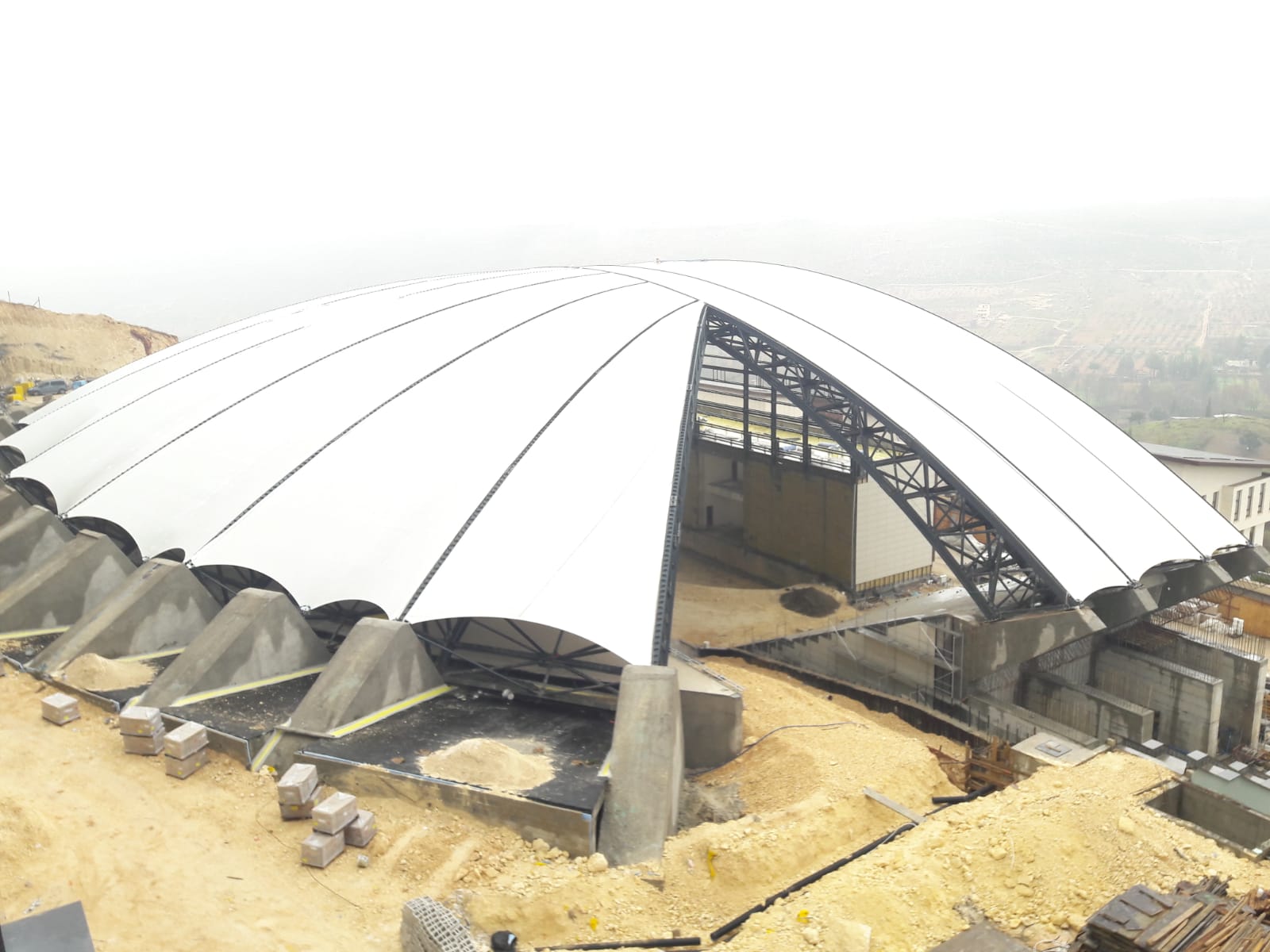

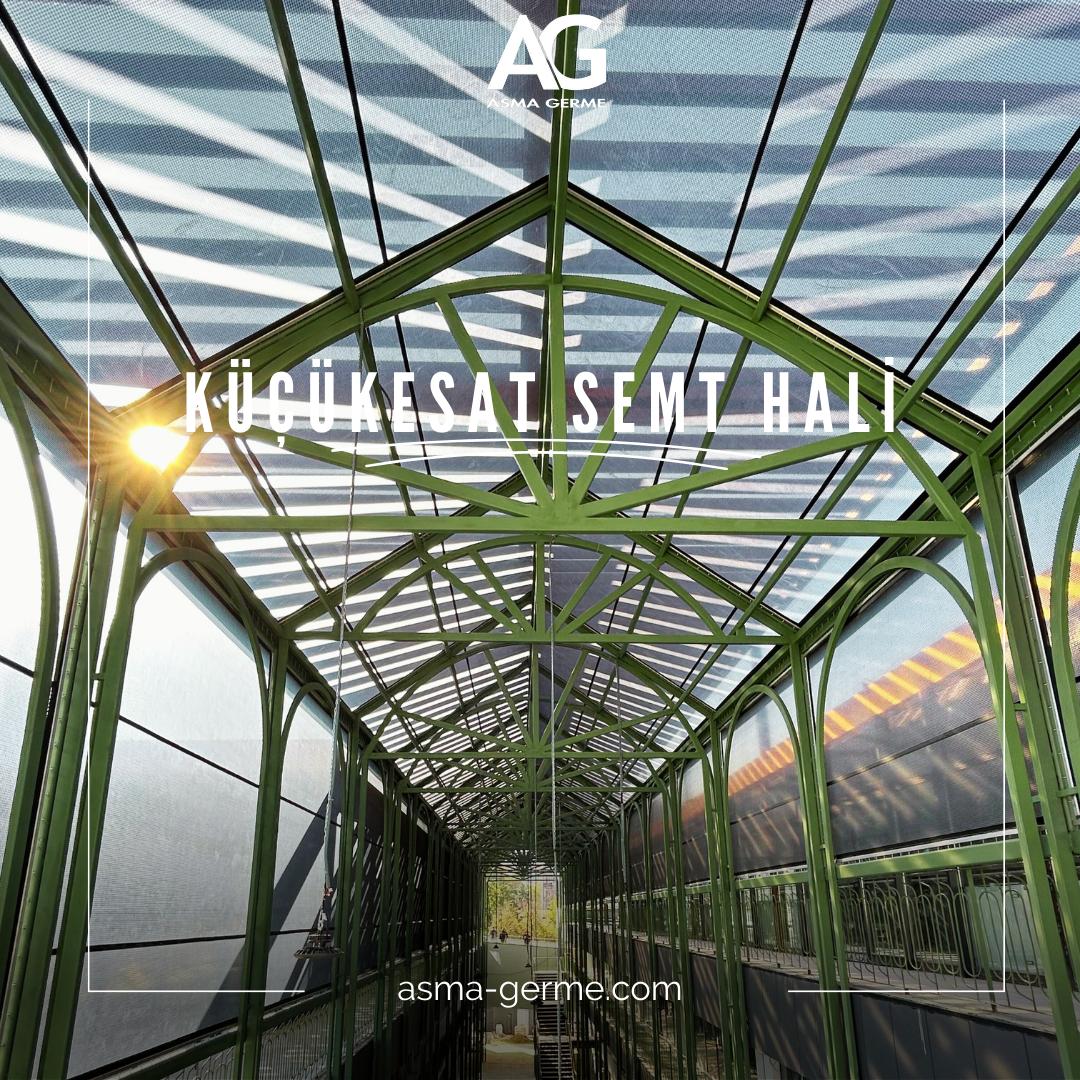

Turning Your Architectural Vision into Reality

With our membrane systems and tension solutions, we add an innovative and aesthetic perspective to modern architecture.

We build future architectural projects with sustainable, innovative and aesthetic solutions.